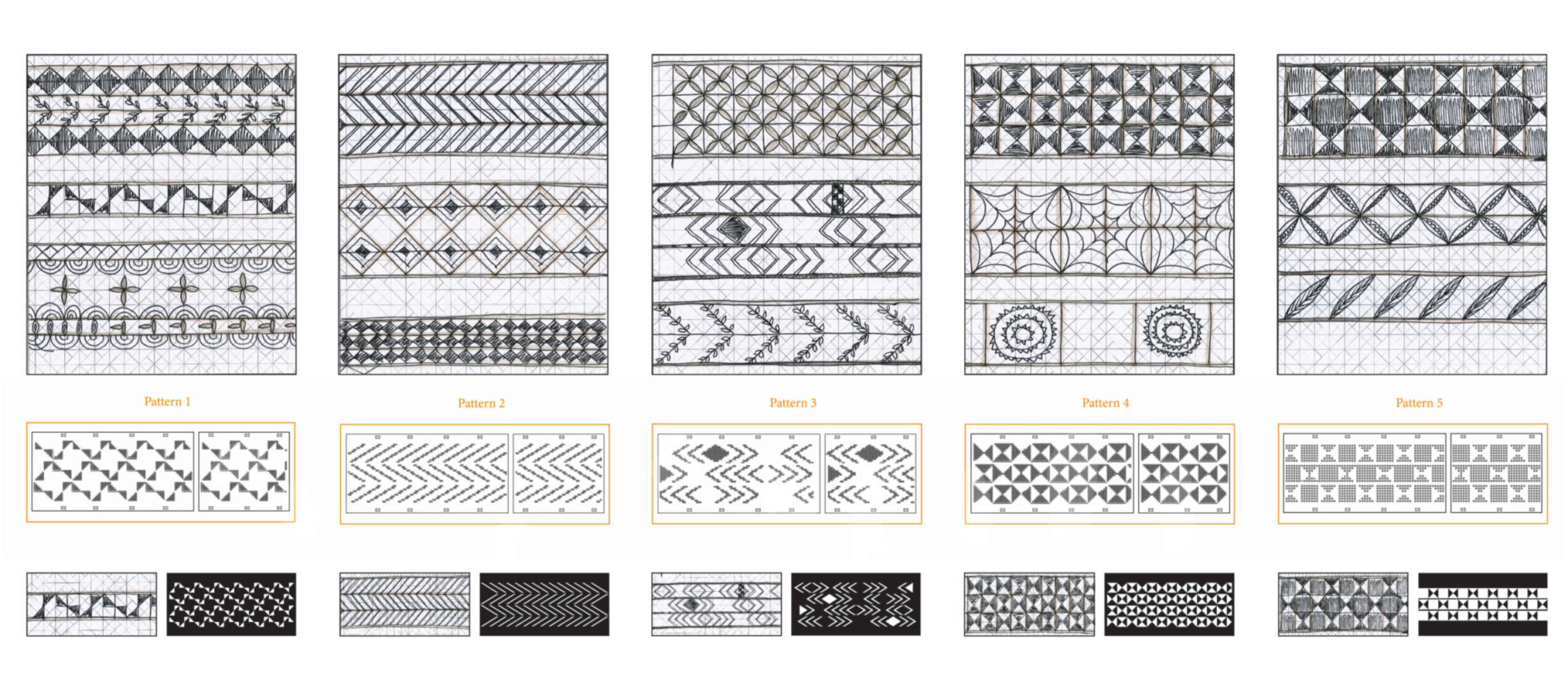

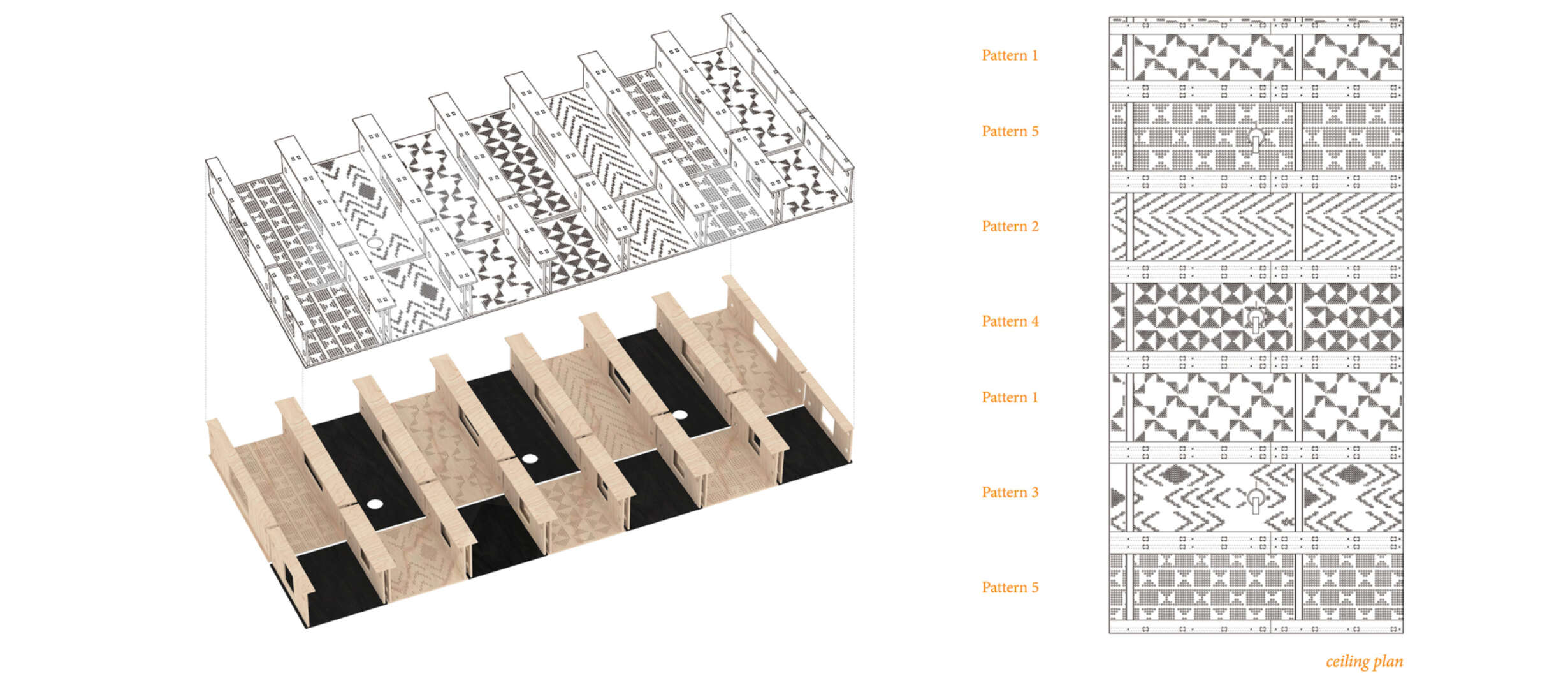

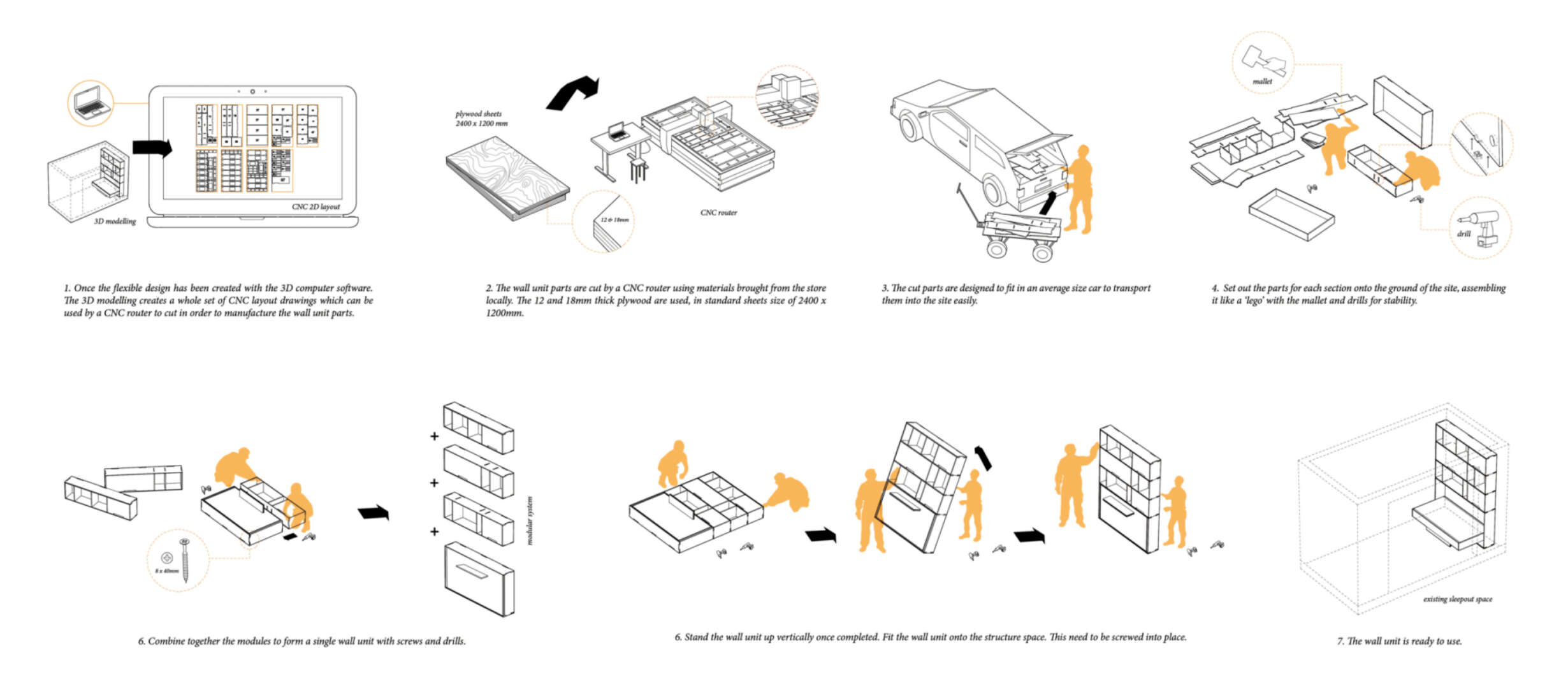

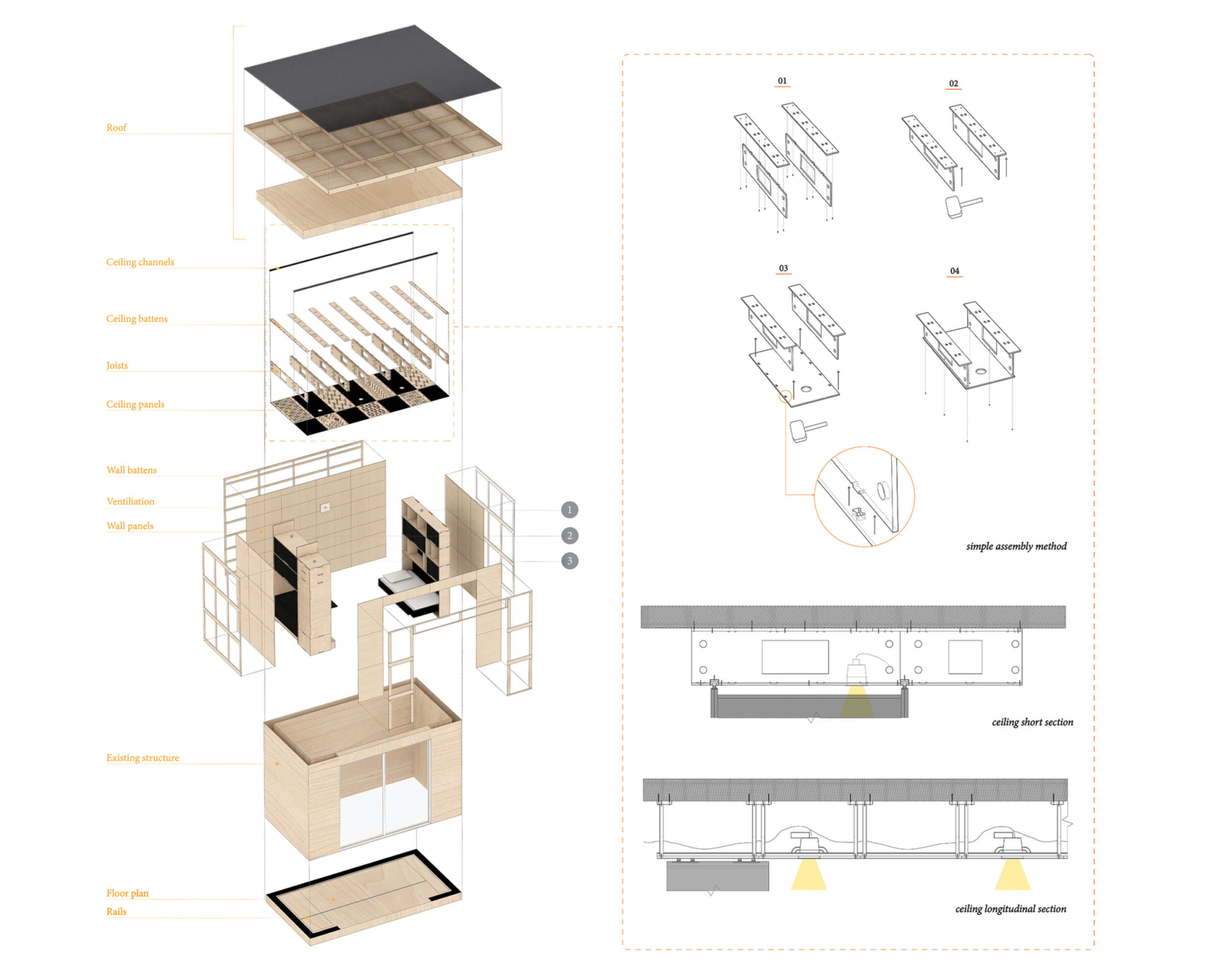

Technological advancements in manufacturing processes have allowed highly accurate, automated tools to manufacture ingenious structures. Engaging with the latest automated technologies (such as a CNC router - Computer Numerical Control) for prefabricated projects, allows for customisable configuration, easier construction methods, efficient construction time, and flexible space once the design has been created.

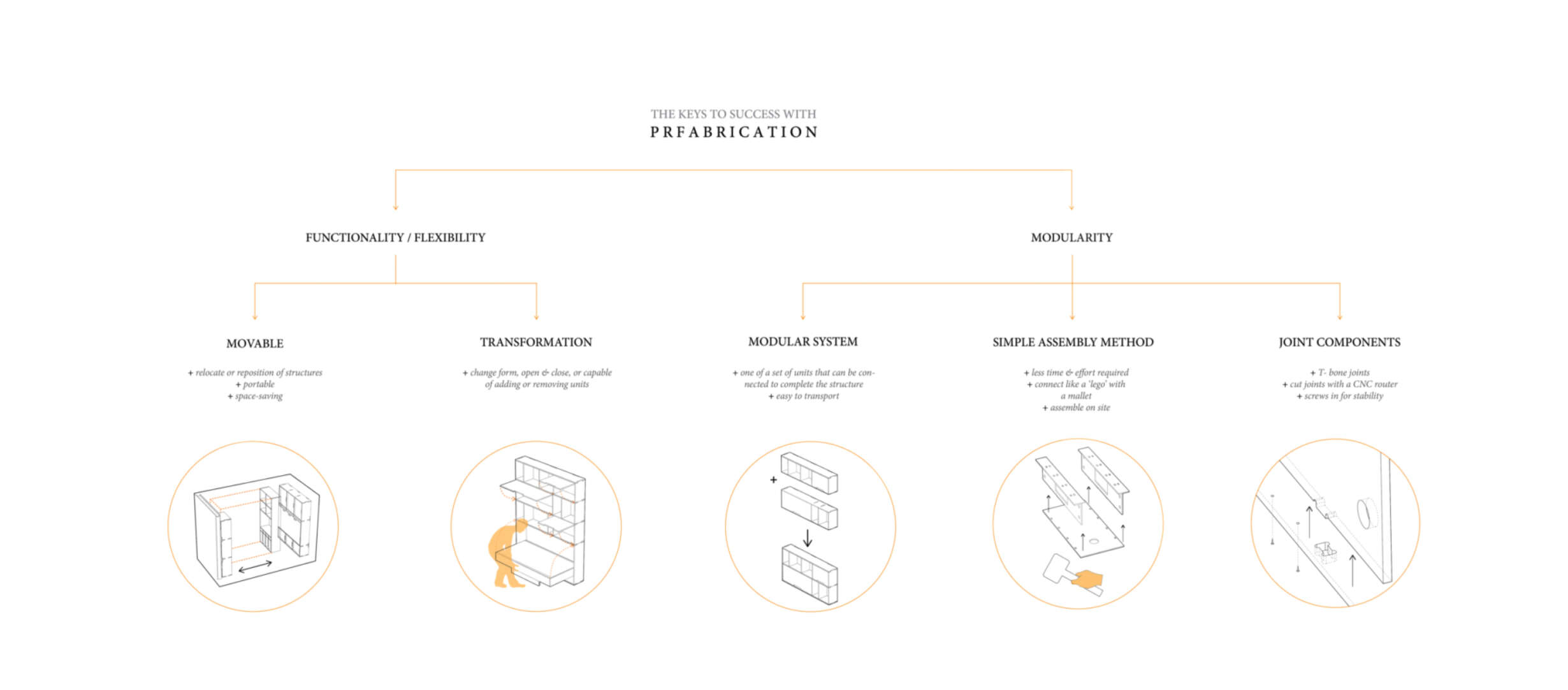

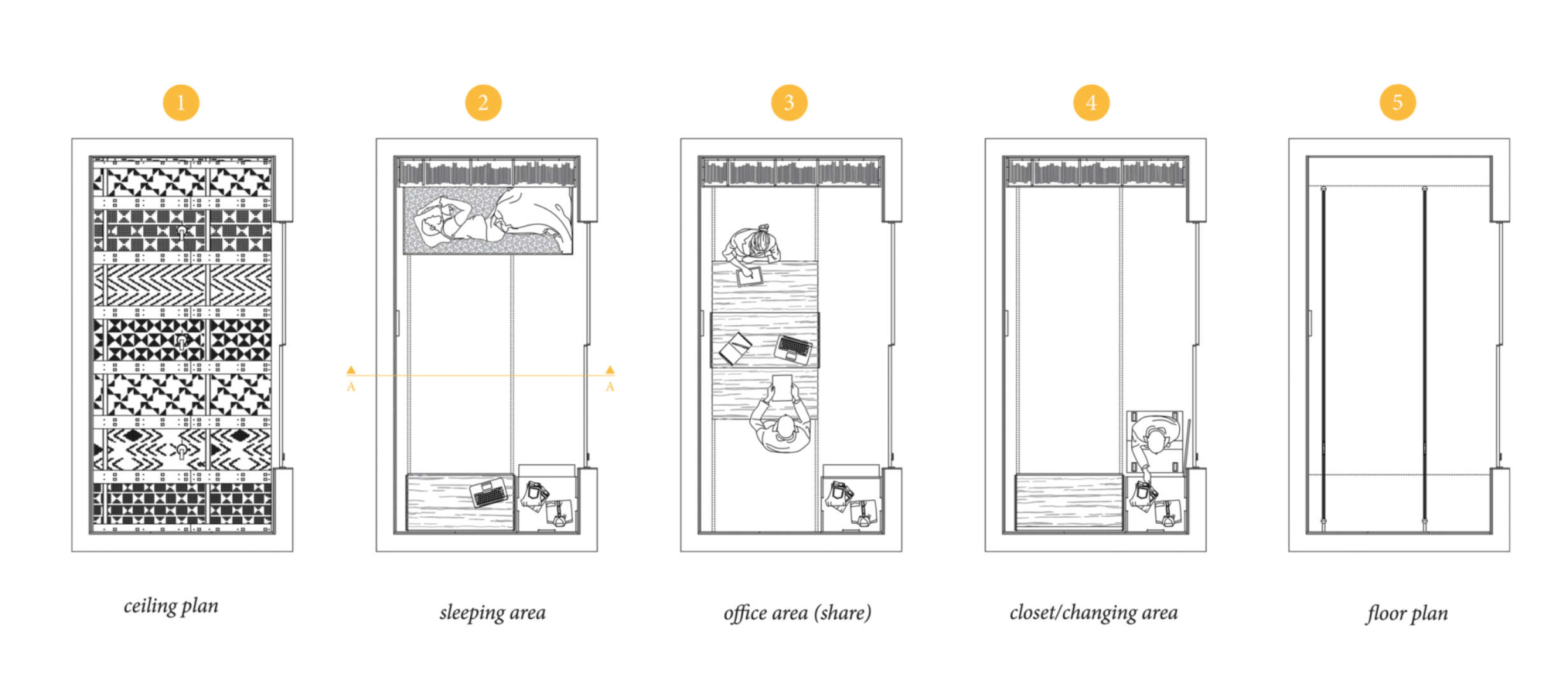

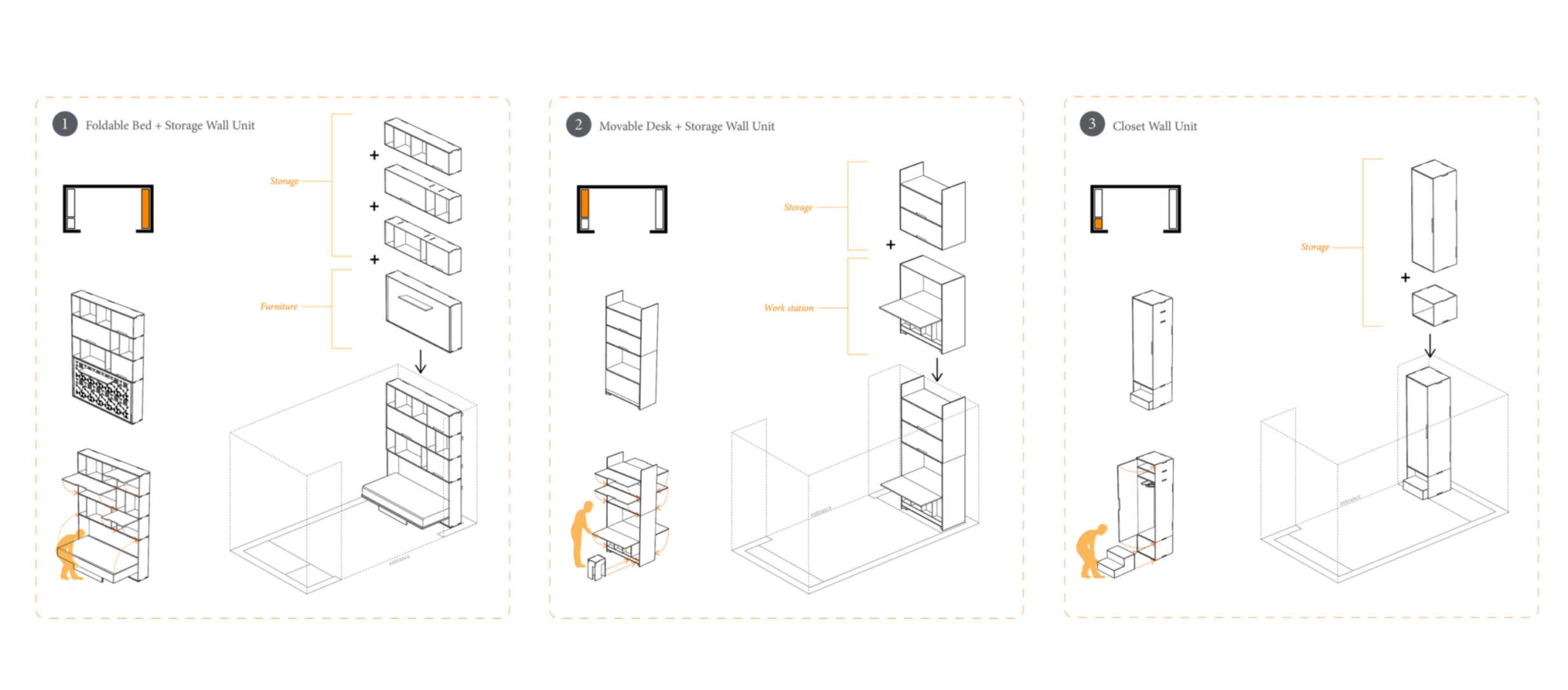

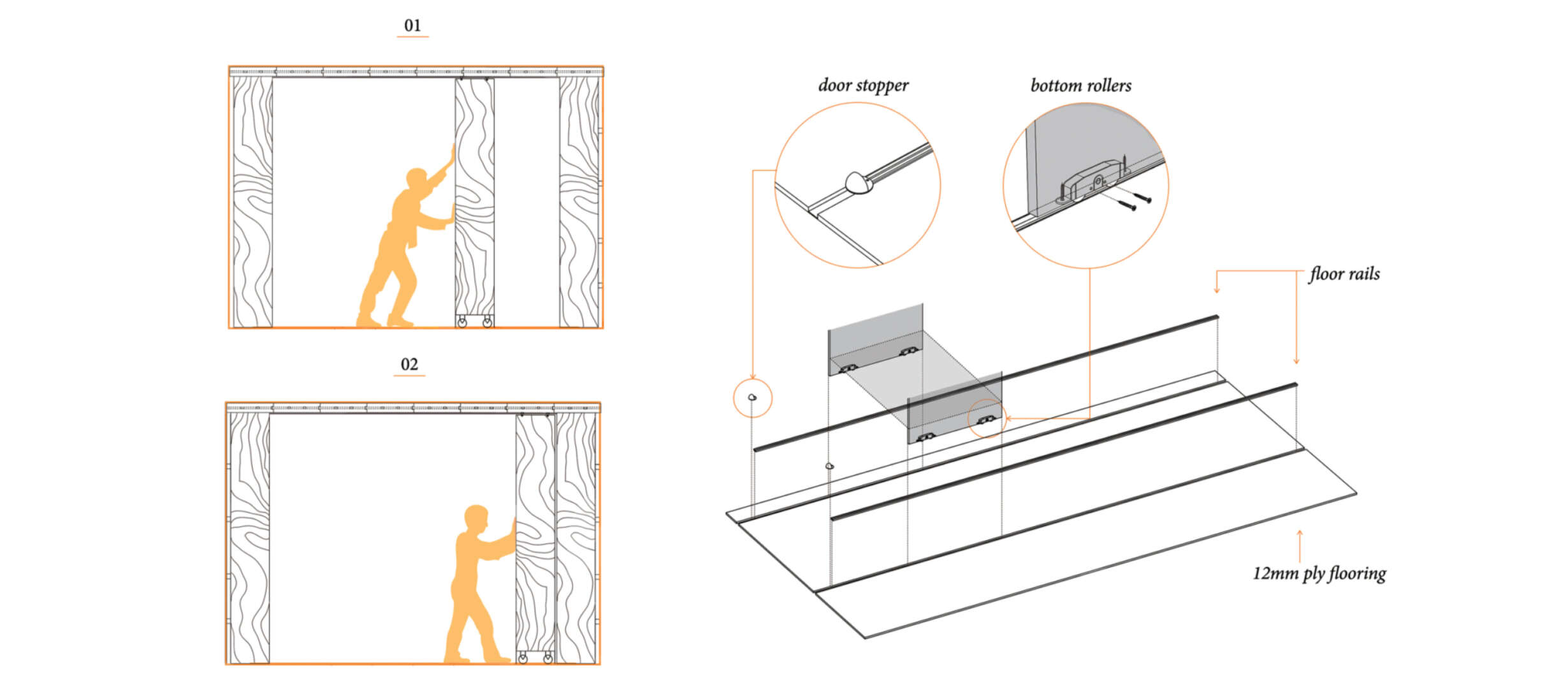

New Zealand based architectural design practices such as Makers of Architecture have manufactured flexible, prefabricated systems utilising digital fabrication technologies that can be easily assembled on site. This practice has become successful due to architectural solutions that are responsively and individually customised, affordable, efficient and sustainable, as well as being spatially engaging. Flexibility, functionality, modularity such as joint components and simple assembly methods that require less time and effort, and continual improvement are the keys to success with prefabrication.